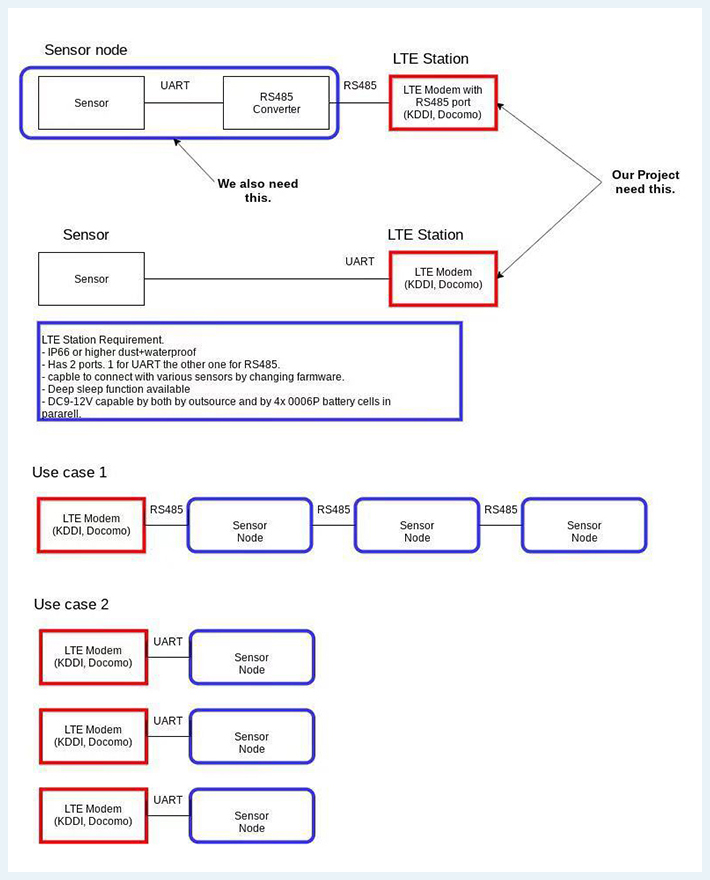

Industry 4.0 is an era in which information technology is used to promote industrial change. In such an intelligent era, technology can improve our production efficiency in multiple dimensions. Traditional industrial field data collection usually uses sensors to deploy independently, and dedicated staff is responsible for reading the statistical data point by point.

For resource optimization and industrial efficiency improvement, many industrial production systems are gradually carrying out improvement plans.

We have learned from some manufacturers who have worked closely with M5 that before contacting M5 products, the manufacturer's internal R&D engineers used the water-proof protective box + Arduino PCB board scheme. Although it can fit basic functions demand, the bare PCB has always made people unsafe. And every new feature addition and modification is a challenge to the time cost. In addition to the ugliness, the way to add a protective box is also a cost control test.

Based on the above common problems, after the actual evaluation and use experience of various market products, many R&D engineers chose M5, a brand with a complete software and hardware system.

Compared with the traditional recording method, the addition of M5Stack hardware products has accelerated the transformation of Industry 4.0 in the production environment data collection method.

Simple, reliable, and highly integrated master control equipment and sensors can quickly and efficiently deploy on-site nodes and reliably collect industry on-site data.

The minute the pressure of each valve and the number of movements of the operating bed are accurately measured by sensors and embedded master control devices and gathered through the cloud to the visualized background panel, there is no need to check one by one on the person.

Easily control the working status of all equipment and the data change curve.

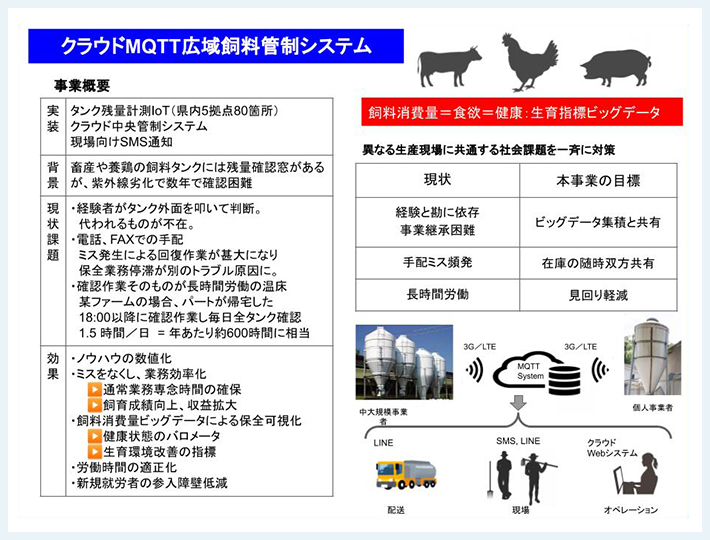

Livestock has the longest history of traditional industry.

The technological development of Industry 4.0, to a certain extent, has also promoted the industrial transformation of the animal husbandry industry.

How to make livestock management more "intelligent" "cutting-edge livestock" "smart farm". This kind of vocabulary appeared in the eyes of people.

In order to improve the efficiency of work, many farmers have also begun to develop IoT solutions that can be applied to their own animal husbandry operation system.

Combining the current technology to optimize the traditional breeding scheme, it has a considerable promotion effect on the management of the livestock life cycle and sales.

Our project manager learned from a pig breeding base in Japan that the basic pig breeding requires a macroscopic process of raising, achieving weight detection, screening, and selling.

In view of the optimization of the efficiency of animal husbandry nuclear operations, combined with actual operation scenarios.

Through the analysis of user pain points, M5 puts forward some suitable solutions for some problems currently encountered in the livestock industry.

For the preliminary sorting of the pigs that meet the standards, we used the ESP32-CAM wireless WIFI camera program to take pictures of the livestock in the breeding pen at regular intervals and upload them to the cloud to perform AI analysis on the individuals who meet the standards. Tracking marks, the automatic output of corresponding list sets, prompting the breeder to weigh the individuals in the set for the next step of testing.

An embedded "weighing area"(embedded weighing sensor and high-precision ADC conversion core, combined with the IoT main control CORE to realize wireless data upload) is deployed at a fixed point in the pigsty. The weight information can be automatically recorded by pulling the livestock to the specified area, forming a streamlined operation and accelerating work efficiency.

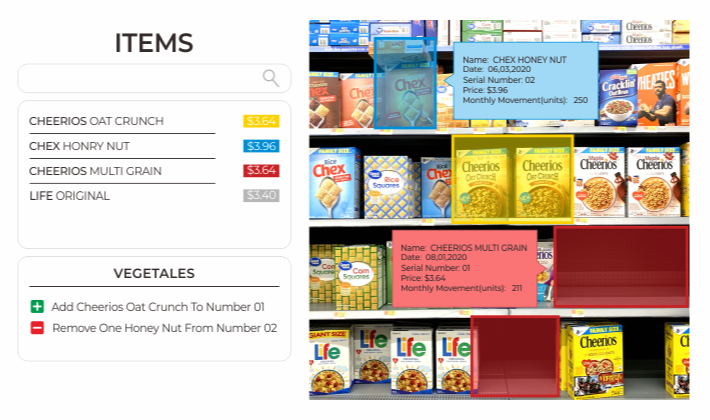

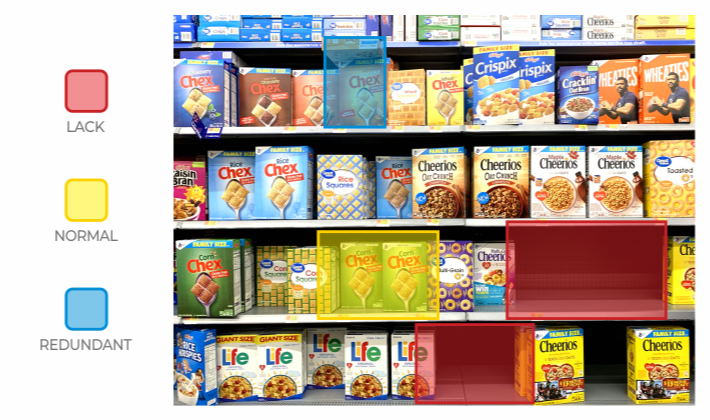

Out-of-stock (OOS), also known as Stockouts, are among the most frustrating experiences for online and in-store shoppers.

Retailers are missing out on nearly $1 trillion in sales because they don't have on hand what customers want to buy in their stores, according to a study conducted by IHL Group.Shoppers encounter out-of-stocks as often as one in three shopping trips, according to the report.(source)

And almost a third of shoppers ended up turning to Amazon when the product they wanted wasn't in stock at their local store.

Applying with Low-power consumption Timer Camera launched by M5Stack, it can effectively take pictures of shelves at regular intervals, connect to the WIFI network, upload to cloud server, and analyze the inventory of shelves with deep learning algorithm. Instantly analyze and alert the staff with the OOS products and locations.

Compared to the traditional operation procedure, M5Stack hardware solution simplifies the inspection process for store managers, and avoids the potential loss of orders caused by products shortage, from store to store. That is also a big help in freeing up labor resources.

Simple, reliable, and highly integrated TimerCAM can instantly and efficiently deploy on-site to monitor on-shelf data.

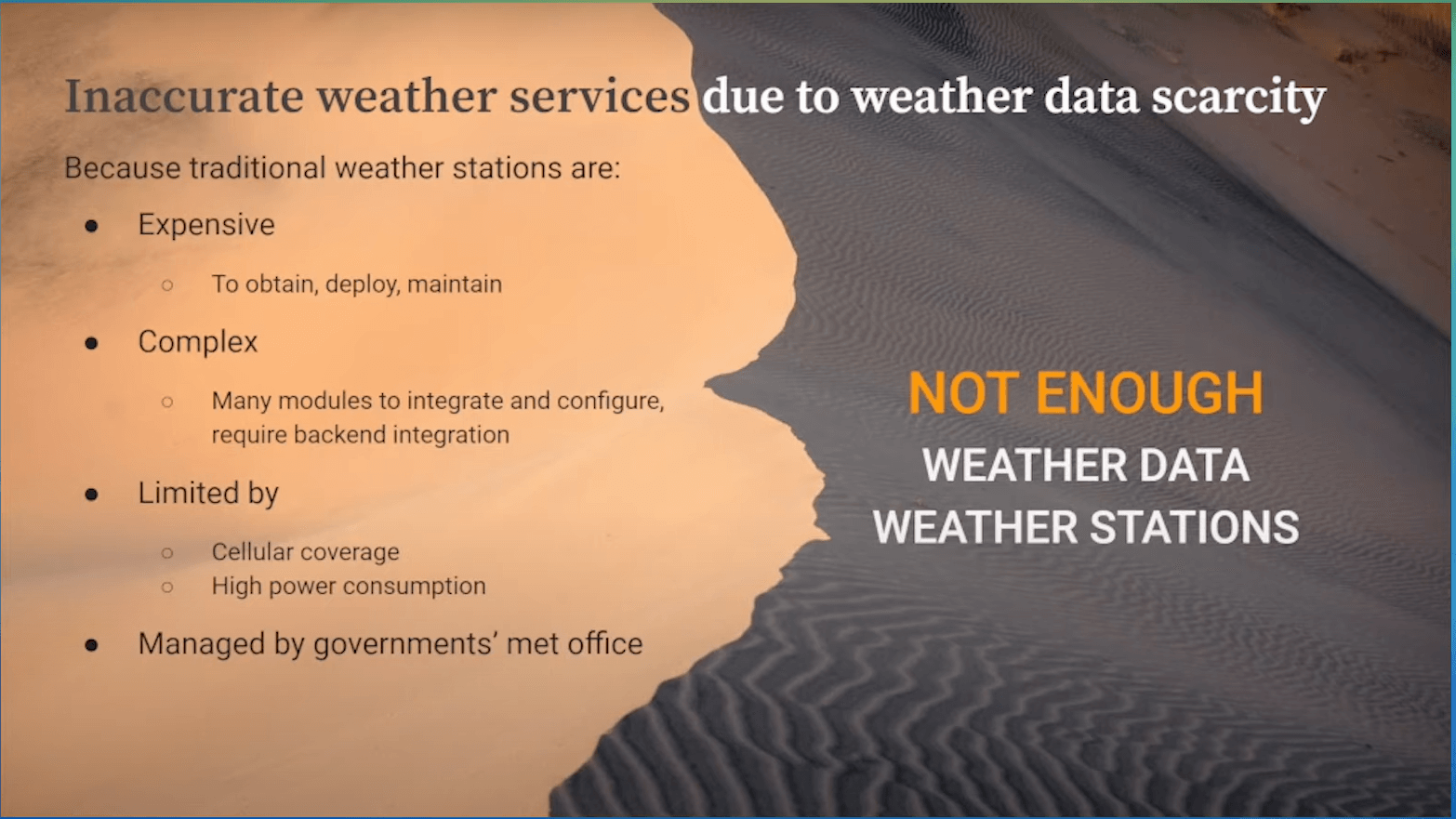

Weather forecast models are often used to simulate the weather and predict future weather conditions. However, weather forecasting models do not give completely accurate weather forecasts. This is why weather forecasting software usually presents the probability of precipitation (rain/snow) as a percentage.

In recent 20 years, extreme weather events such as droughts and floods occur more frequently and with greater severity as forecast models fail.

Increasingly erratic weather patterns are already having a significant impact on the lives of humanbeings and food security around the world. Accurate climate and weather information helps people to be able to plan ahead and adapt to climate change. However, to improve weather forecasting, it is first necessary to be able to monitor the weather.

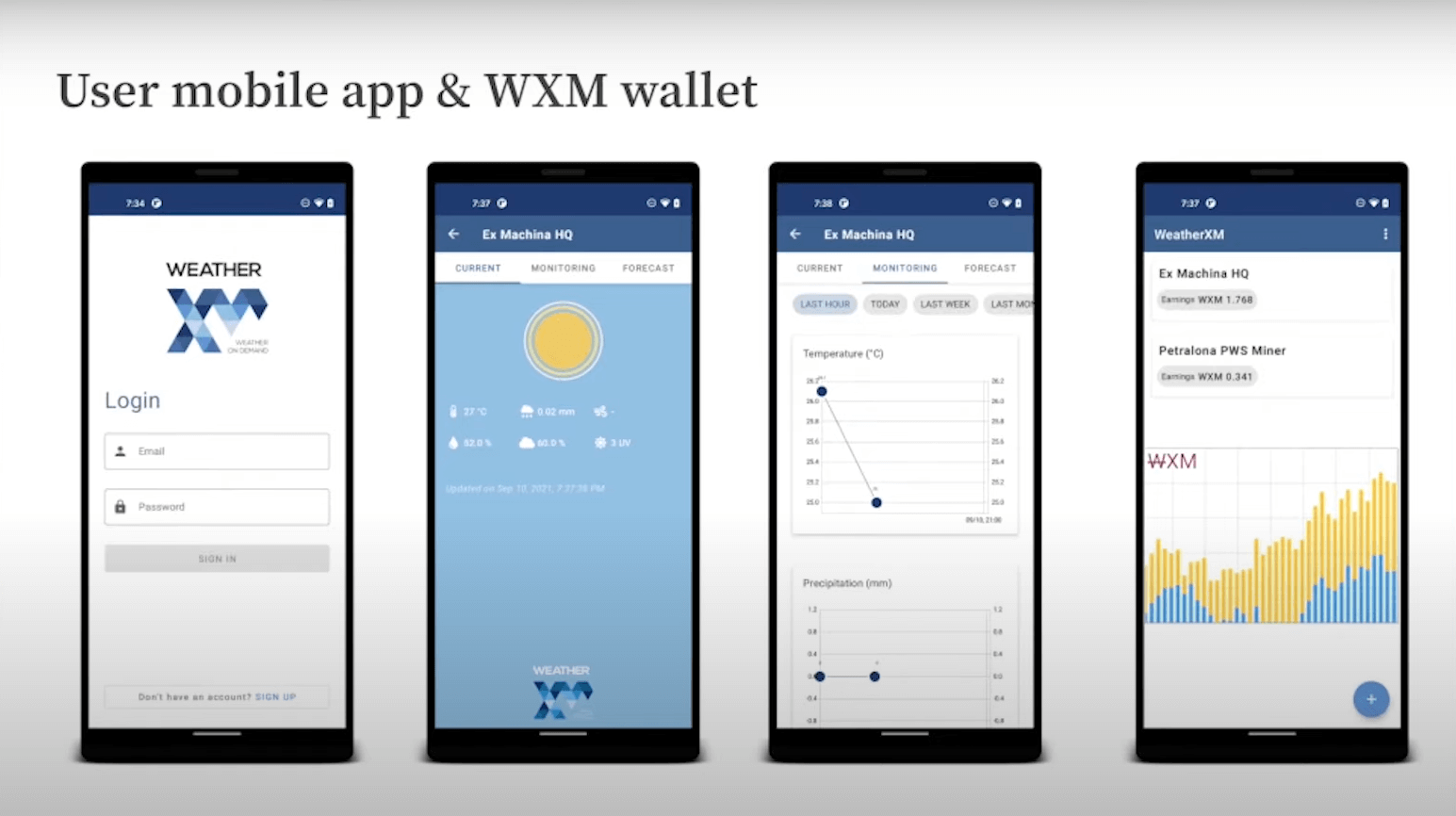

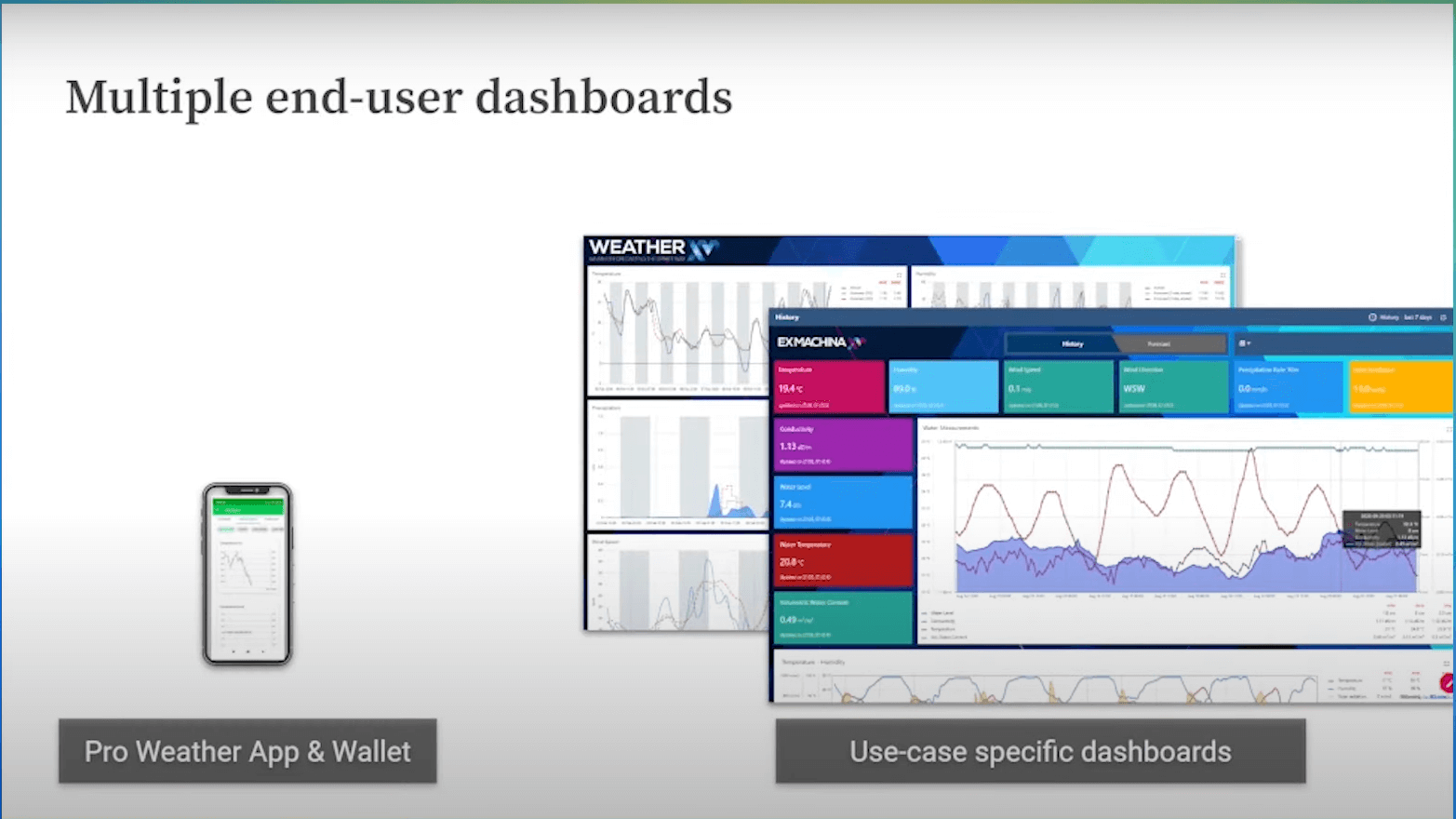

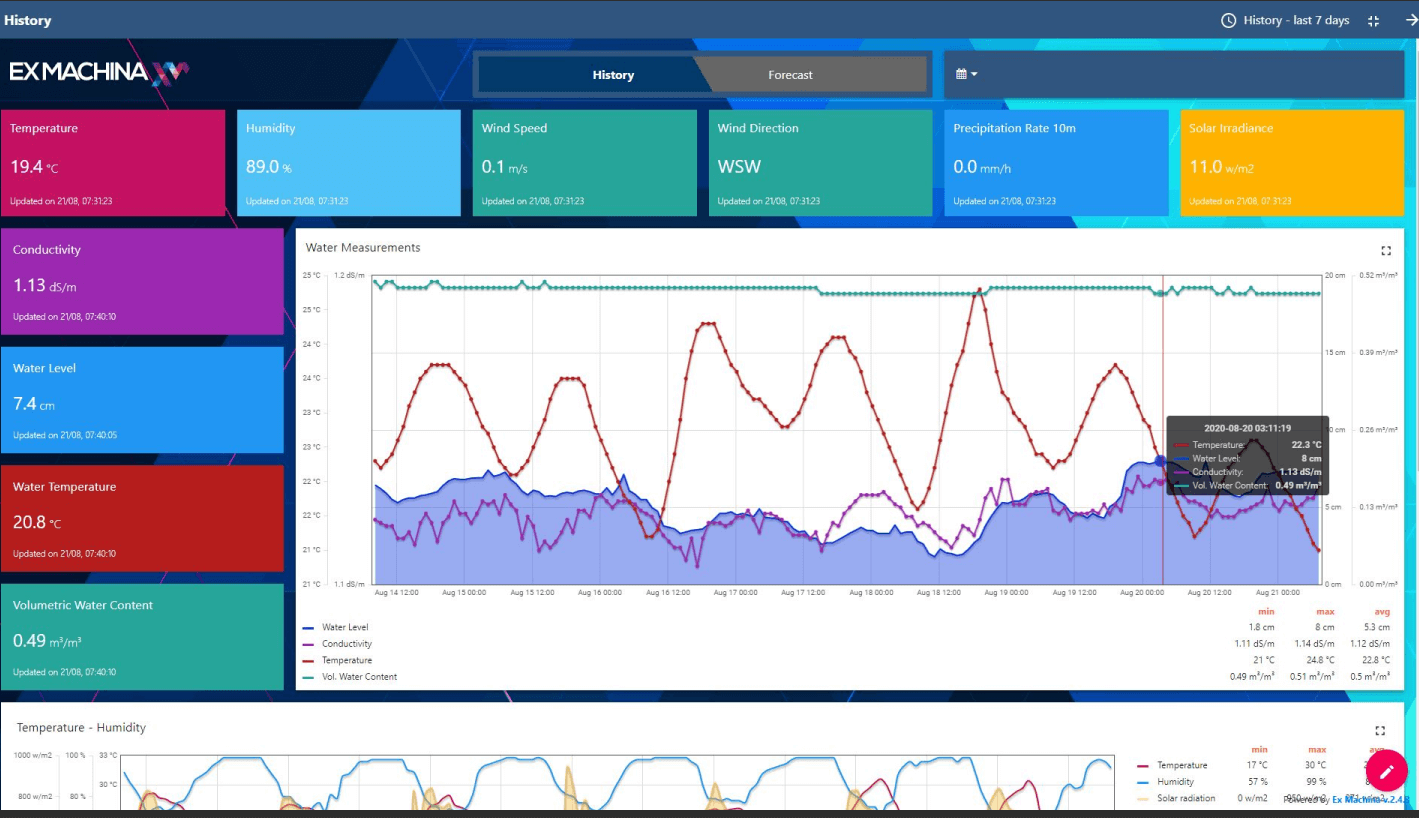

Technology can help improve weather forecasts in a variety of ways. One of them is via the weather network– WeatherXM. WeatherXM is a weather networking community leveraging Web3, IoT, and machine learning technologies to bring about a paradigm shift in weather data collection and positively impact the planet and the lives of millions of people on it. As a partner of M5Stack, WeatherXM is using M5Stack hardware to collect high-quality, hyperlocal weather data and make it generally available, to create impactful change for industries that rely heavily on accurate weather readings.

WeatherXM, based in Greece, is a company to make a global weather network for people to get hyper-local accurate forecasts, suitable for agriculture, energy, outdoor sports, maritime, or any other use case. It can build small weather stations that can be deployed in previously inaccessible areas and collect valuable information. And WeatherXM has developed a number of advanced weather and environmental solutions and delivered thousands of smart weather stations to customers around the world. And now it’s currently producing more to meet customers’ demand and expand its range with a new version that connects more easily with M5Core2, which is much easier for users to deploy.

The most important part of this Web3-compatible, integrated solution is M5Core2. M5Core2 has a 2.0" integrated capacitive touch screen to provide a smoother human-computer interaction experience. With the function of GPS + LoRA + WiFi communication, it features low-power consumption, easy deployment, remote transmission, real-time data transmission and OTA functions. Moreover, the device is equipped with a built-in ATECC608 hardware encryption chip, which can enhance the security of the device's IoT communication process by means of hardware-level keys. Users can view the data at any time on their mobile phones and computers.