In this article, we’ll integrate the M5Stack Dial into Home Assistant (HA) — a multifunctional system with many interesting features to control our setup.

Index

M5Stack Dial

M5Stack is already a well-known brand to us, with creations like the M5Stack CoreS3SE and the classic Atom Echo. Today, we are going to integrate the M5Stack Dial into Home Assistant — a device that includes the following components:

All these features packed into a single, ready-to-use device which make the M5Dial a truly compelling gadget. And since it's powered by an ESP32-S3, we can easily integrate it into Home Assistant using ESPHome.

Mr. Avocado

As usual, we wanted to make the most of these features by building a fun and practical project. This time, it's something special — a device co-designed with our Patreon community.

We named it Mr. Avocado, a playful nod to the iconic “Mr. Potato.” The goal was to create a multifunctional device with the following capabilities:

Prerequisites

To integrate the M5Dial into Home Assistant, you’ll need:

🥑 If you’re just getting started with ESPHome, I highly recommend checking out the academy workshop — it’s a great way to get the most out of it!

Follow these steps to integrate the M5Stack Dial into Home Assistant:

1. In Home Assistant, open the ESPHome add-on, click “New Device”, then “Continue.”

2. Give your device a name (for example, “M5Stack Dial”) and click “Next.”

3. For the device type, select “ESP32-S3.” You’ll see that a new tile has been created for your device.

4. Click “Skip”, then “Edit” on your device’s tile. Copy the default code that appears and save it—you’ll need parts of it later.

5. Now, copy the code below and use it to replace the default code in ESPHome.

substitutions:

# Device customization

# Personalización del dispositivo

name: m5stack-dial

friendly_name: M5Stack Dial

background_color: 'fab02b'

background_image: https://aguacatec.es/wp-content/uploads/2025/02/mravocado_background_white.jpg

background_image_saver: https://aguacatec.es/wp-content/uploads/2025/02/mravocado_bg_off.jpg

background_image_device: https://aguacatec.es/wp-content/uploads/2025/02/mravocado_bg_device.jpeg

# Icons

# Iconos

icon_1: mdi:led-strip-variant

icon_2: mdi:thermostat

icon_3: mdi:robot-vacuum

icon_4: mdi:printer

icon_5: mdi:printer-3d-nozzle

icon_6: mdi:fan

icon_7: mdi:air-humidifier

icon_8: mdi:ceiling-light

# Sounds

# Sonidos

menu_sound: 'beep:d=64,o=5,b=255:c7'

alarm_sound: 'xmen:d=4,o=6,b=200:16f#5,16g5,16b5,16d,c#,8b5,8f#5,p,16f#5,16g5,16b5,16d,c#,8b5,8g5,p,16f#5,16g5,16b5,16d,c#,8b5,8d,2p,8c#,8b5,2p'

# Example of Lights

# Ejemplo de Luces

desk_led: light.tira_led_escritorio

lamp: light.lampara

# Example of Thermostat

# Ejemplo de Termostatos

climate: climate.salon

aircon: climate.aircon

# Example of Vacuum

# Ejemplo de Aspirador

vacuum: vacuum.robot_aspirador

# Example of Switches

# Ejemplo de Enchufes

printer: switch.regleta_l3

printer3d: switch.regleta_l4

# Example of dehumidifier

# Ejemplo de Deshumidificador

dehumidifier: humidifier.deshumidificador

# NFC/RFID Tags

# Etiquetas NFC/RFID

# tag1: C3-DB-4F-28

# tag2: 03-55-E5-13

# Other settings

# Otros ajustes

allowed_characters: " ¿?¡!#%'()+,-./:°0123456789ABCDEFGHIJKLMNOPQRSTUVWYZabcdefghijklmnopqrstuvwxyzáéíóú"

################################################################################################################

esphome:

name: ${name}

friendly_name: ${friendly_name}

on_boot:

then:

- pcf8563.read_time:

- display.page.show: home

platformio_options:

board_build.flash_mode: dio

esp32:

board: esp32-s3-devkitc-1

flash_size: 8MB

framework:

type: esp-idf

wifi:

ssid: !secret wifi_ssid

password: !secret wifi_password

# Enable fallback hotspot (captive portal) in case wifi connection fails

ap:

ssid: "M5Stack-Dial Fallback Hotspot"

password: "Aosad564JQR"

api:

encryption:

key: "QYmasdasdsd71H8/dlyD1BI5cU10X234234fhg="

services:

- service: play_sound

variables:

song: string

volume: int

then:

- lambda: "id(script_rtttl_play).execute(song, volume);"

script:

- id: script_rtttl_play

parameters:

song: string

volume: int

mode: single

then:

- lambda: |-

float volume_f = (volume>0) ? ((float)clamp(volume, 0, 100))/100.0f : 1.0f;

id(buzzer).set_max_power(volume_f);

- rtttl.play:

rtttl: !lambda 'return (song.find('':'') == std::string::npos) ? ("song:d=16,o=5,b=100:" + song).c_str() : song.c_str();'

ota:

- platform: esphome

password: "0935e9dsasdfgdb3d8934c"

logger:

captive_portal:

binary_sensor:

- platform: gpio

name: "Front Button"

id: front_button

pin:

number: GPIO42

inverted: true

internal: true

on_press:

then:

- if:

condition:

switch.is_on: menu_sounds

then:

- rtttl.play: ${menu_sound}

- if:

condition:

light.is_on: backlight

then:

- if:

condition:

display.is_displaying_page: device_control

then:

- if:

condition:

lambda: |-

return id(device) == 1;

then:

- homeassistant.action:

service: light.toggle

data:

entity_id: ${desk_led}

- if:

condition:

lambda: |-

return id(device) == 2;

then:

- homeassistant.action:

service: climate.toggle

data:

entity_id: ${climate}

- if:

condition:

lambda: |-

return id(device) == 3;

then:

- if:

condition:

lambda: 'return id(device_vacuum).state == "cleaning";'

then:

- homeassistant.action:

service: vacuum.pause

data:

entity_id: ${vacuum}

else:

- homeassistant.action:

service: vacuum.start

data:

entity_id: ${vacuum}

- if:

condition:

lambda: |-

return id(device) == 4;

then:

- homeassistant.action:

service: switch.toggle

data:

entity_id: ${printer}

- if:

condition:

lambda: |-

return id(device) == 5;

then:

- homeassistant.action:

service: switch.toggle

data:

entity_id: ${printer3d}

- if:

condition:

lambda: |-

return id(device) == 6;

then:

- homeassistant.action:

service: climate.toggle

data:

entity_id: ${aircon}

- if:

condition:

lambda: |-

return id(device) == 7;

then:

- homeassistant.action:

service: humidifier.toggle

data:

entity_id: ${dehumidifier}

- if:

condition:

lambda: |-

return id(device) == 8;

then:

- homeassistant.action:

service: light.toggle

data:

entity_id: ${lamp}

- if:

condition:

display.is_displaying_page: locked_screen

then:

- switch.turn_on: mravocado_display

- light.turn_on:

id: backlight

brightness: 100%

- display.page.show: home

- if:

condition:

display.is_displaying_page: home

then:

- if:

condition:

lambda: |-

return id(device) > 0;

then:

- light.turn_on:

id: backlight

brightness: 100%

- display.page.show: device_control

else:

- switch.turn_on: mravocado_display

- light.turn_on:

id: backlight

brightness: 100%

- display.page.show: home

- lambda: |-

id(inactivity_time) = 0;

- platform: gpio

name: Hold Button

pin: GPIO46

internal: True

- platform: touchscreen

name: "Home Button"

internal: true

x_min: 0

x_max: 240

y_min: 0

y_max: 80

page_id: device_control

on_press:

- display.page.show: home

- if:

condition:

switch.is_on: menu_sounds

then:

- rtttl.play: ${menu_sound}

- lambda: |-

id(inactivity_time) = 0;

- platform: touchscreen

name: "Device Button"

internal: true

x_min: 81

x_max: 160

y_min: 80

y_max: 240

page_id: device_control

on_press:

- if:

condition:

switch.is_on: menu_sounds

then:

- rtttl.play: ${menu_sound}

- if:

condition:

lambda: |-

return id(device) == 1;

then:

- homeassistant.action:

service: light.toggle

data:

entity_id: ${desk_led}

- if:

condition:

lambda: |-

return id(device) == 2;

then:

- homeassistant.action:

service: climate.toggle

data:

entity_id: ${climate}

- if:

condition:

lambda: |-

return id(device) == 3;

then:

- if:

condition:

lambda: 'return id(device_vacuum).state == "cleaning";'

then:

- homeassistant.action:

service: vacuum.pause

data:

entity_id: ${vacuum}

else:

- homeassistant.action:

service: vacuum.start

data:

entity_id: ${vacuum}

- if:

condition:

lambda: |-

return id(device) == 4;

then:

- homeassistant.action:

service: switch.toggle

data:

entity_id: ${printer}

- if:

condition:

lambda: |-

return id(device) == 5;

then:

- homeassistant.action:

service: switch.toggle

data:

entity_id: ${printer3d}

- if:

condition:

lambda: |-

return id(device) == 6;

then:

- homeassistant.action:

service: climate.toggle

data:

entity_id: ${aircon}

- if:

condition:

lambda: |-

return id(device) == 7;

then:

- homeassistant.action:

service: humidifier.toggle

data:

entity_id: ${dehumidifier}

- if:

condition:

lambda: |-

return id(device) == 8;

then:

- homeassistant.action:

service: light.toggle

data:

entity_id: ${lamp}

- lambda: |-

id(inactivity_time) = 0;

- platform: touchscreen

name: "Minus Button"

internal: true

x_min: 0

x_max: 80

y_min: 80

y_max: 240

page_id: device_control

on_press:

- if:

condition:

switch.is_on: menu_sounds

then:

- rtttl.play: ${menu_sound}

- if:

condition:

display.is_displaying_page: device_control

then:

- if:

condition:

lambda: |-

return id(device) == 1;

then:

- homeassistant.action:

service: light.turn_on

data:

entity_id: ${desk_led}

brightness_step_pct: '-10'

- if:

condition:

lambda: |-

return id(device) == 2;

then:

- homeassistant.action:

service: climate.set_temperature

data:

entity_id: ${climate}

data_template:

temperature: '{{ my_variable | float }}'

variables:

my_variable: |-

return id(thermostat_temperature).state - 1.0;

- if:

condition:

lambda: |-

return id(device) == 6;

then:

- homeassistant.action:

service: climate.set_temperature

data:

entity_id: ${aircon}

data_template:

temperature: '{{ my_variable | float }}'

variables:

my_variable: |-

return id(aircon_temperature).state - 1.0;

- if:

condition:

lambda: |-

return id(device) == 7;

then:

- homeassistant.action:

service: humidifier.set_humidity

data:

entity_id: ${dehumidifier}

data_template:

humidity: '{{ my_variable | float }}'

variables:

my_variable: |-

return id(dehumidifier_humidity).state - 5.0;

- if:

condition:

lambda: |-

return id(device) == 8;

then:

- homeassistant.action:

service: light.turn_on

data:

entity_id: ${lamp}

brightness_step_pct: '-10'

- lambda: |-

id(inactivity_time) = 0;

- platform: touchscreen

name: "Plus Button"

internal: true

x_min: 161

x_max: 240

y_min: 80

y_max: 240

page_id: device_control

on_press:

- if:

condition:

switch.is_on: menu_sounds

then:

- rtttl.play: ${menu_sound}

- if:

condition:

display.is_displaying_page: device_control

then:

- if:

condition:

lambda: |-

return id(device) == 1;

then:

- homeassistant.action:

service: light.turn_on

data:

entity_id: ${desk_led}

brightness_step_pct: '10'

- if:

condition:

lambda: |-

return id(device) == 2;

then:

- homeassistant.action:

service: climate.set_temperature

data:

entity_id: ${climate}

data_template:

temperature: '{{ my_variable | float }}'

variables:

my_variable: |-

return id(thermostat_temperature).state + 1.0;

- if:

condition:

lambda: |-

return id(device) == 3;

then:

- homeassistant.action:

service: vacuum.return_to_base

data:

entity_id: ${vacuum}

- if:

condition:

lambda: |-

return id(device) == 6;

then:

- homeassistant.action:

service: climate.set_temperature

data:

entity_id: ${aircon}

data_template:

temperature: '{{ my_variable | float }}'

variables:

my_variable: |-

return id(aircon_temperature).state + 1.0;

- if:

condition:

lambda: |-

return id(device) == 7;

then:

- homeassistant.action:

service: humidifier.set_humidity

data:

entity_id: ${dehumidifier}

data_template:

humidity: '{{ my_variable | float }}'

variables:

my_variable: |-

return id(dehumidifier_humidity).state + 5.0;

- if:

condition:

lambda: |-

return id(device) == 8;

then:

- homeassistant.action:

service: light.turn_on

data:

entity_id: ${lamp}

brightness_step_pct: '10'

- lambda: |-

id(inactivity_time) = 0;

# - platform: rc522

# uid: ${tag1}

# name: "NFC Tag"

# on_press:

# - homeassistant.action:

# service: light.toggle

# data:

# entity_id: ${desk_led}

button:

- platform: template

name: "Alarm"

id: alarm_sound

icon: "mdi:bell-ring"

on_press:

- rtttl.play: ${alarm_sound}

- switch.turn_on: screen_saver

- lambda: |-

id(inactivity_time) = 0;

color:

- id: background_color

hex: ${background_color}

- id: icon_on

hex: 'f28800'

- id: icon_off

hex: 'e7aa77'

- id: icon_big_on

hex: 'ffebbf'

- id: icon_big_off

hex: 'f78f1d'

- id: dark_orange

hex: 'd2750b'

- id: light_orange

hex: 'f9c699'

font:

- file: "gfonts://Space Grotesk"

id: clock_time

size: 40

glyphs: ${allowed_characters}

- file: "gfonts://Space Grotesk"

id: secondary

size: 18

glyphs: ${allowed_characters}

globals:

- id: inactivity_time

type: int

restore_value: no

initial_value: '0'

- id: device

type: int

restore_value: no

initial_value: '0'

i2c:

- id: internal_i2c

sda: GPIO11

scl: GPIO12

scan: False

image:

- file: ${background_image}

id: background_image

resize: 245x245

type: RGB

transparency: alpha_channel

- file: ${background_image_saver}

id: background_image_saver

resize: 245x245

type: RGB

transparency: alpha_channel

- file: ${background_image_device}

id: background_image_device

resize: 245x245

type: RGB

transparency: alpha_channel

- file: mdi:home

id: icon_home

resize: 40x40

type: BINARY

transparency: chroma_key

- file: mdi:plus-thick

id: plus

resize: 30x30

type: BINARY

transparency: chroma_key

- file: mdi:minus-thick

id: minus

resize: 30x30

type: BINARY

transparency: chroma_key

- file: mdi:home-map-marker

id: vacuum_dock

resize: 30x30

type: BINARY

transparency: chroma_key

- file: mdi:play-box

id: play_icon

resize: 30x30

type: BINARY

transparency: chroma_key

- file: mdi:pause-box

id: pause_icon

resize: 30x30

type: BINARY

transparency: chroma_key

- file: ${icon_1}

id: icon_1

resize: 33x33

type: BINARY

transparency: chroma_key

- file: ${icon_1}

id: icon_1_big

resize: 100x100

type: BINARY

transparency: chroma_key

- file: ${icon_2}

id: icon_2

resize: 33x33

type: BINARY

transparency: chroma_key

- file: ${icon_2}

id: icon_2_big

resize: 100x100

type: BINARY

transparency: chroma_key

- file: ${icon_3}

id: icon_3

resize: 33x33

type: BINARY

transparency: chroma_key

- file: ${icon_3}

id: icon_3_big

resize: 100x100

type: BINARY

transparency: chroma_key

- file: ${icon_4}

id: icon_4

resize: 33x33

type: BINARY

transparency: chroma_key

- file: ${icon_4}

id: icon_4_big

resize: 100x100

type: BINARY

transparency: chroma_key

- file: ${icon_5}

id: icon_5

resize: 33x33

type: BINARY

transparency: chroma_key

- file: ${icon_5}

id: icon_5_big

resize: 100x100

type: BINARY

transparency: chroma_key

- file: ${icon_6}

id: icon_6

resize: 33x33

type: BINARY

transparency: chroma_key

- file: ${icon_6}

id: icon_6_big

resize: 100x100

type: BINARY

transparency: chroma_key

- file: ${icon_7}

id: icon_7

resize: 33x33

type: BINARY

transparency: chroma_key

- file: ${icon_7}

id: icon_7_big

resize: 100x100

type: BINARY

transparency: chroma_key

- file: ${icon_8}

id: icon_8

resize: 33x33

type: BINARY

transparency: chroma_key

- file: ${icon_8}

id: icon_8_big

resize: 100x100

type: BINARY

transparency: chroma_key

interval:

- interval: 1s

then:

- lambda: |-

id(inactivity_time) += 1;

if (id(auto_lock).state) {

if (id(inactivity_time) > id(screen_saver_time).state && id(inactivity_time) < id(auto_lock_time_out).state ) {

id(screen_saver).turn_on();

}

if (id(inactivity_time) > id(auto_lock_time_out).state) {

id(backlight_pwm).turn_off();

id(mravocado_display).turn_off();

id(screen_saver).turn_off();

}

}

else {

if (id(inactivity_time) > id(screen_saver_time).state) {

id(screen_saver).turn_on();

}

}

light:

- platform: monochromatic

name: "Backlight"

output: backlight_pwm

id: backlight

default_transition_length: 0s

restore_mode: ALWAYS_ON

internal: True

number:

- platform: template

name: "Auto Lock"

id: auto_lock_time_out

icon: "mdi:timer-sand"

optimistic: true

min_value: 20

max_value: 300

step: 10

unit_of_measurement: "s"

restore_value: true

- platform: template

name: "Screen Saver"

id: screen_saver_time

icon: "mdi:screen-rotation-lock"

optimistic: true

min_value: 10

max_value: 300

step: 10

unit_of_measurement: "s"

restore_value: true

output:

- platform: ledc

pin: GPIO3

id: buzzer

- platform: ledc

pin: GPIO9

id: backlight_pwm

#rc522_i2c:

# - i2c_id: internal_i2c

# id: tag_reader

# address: 0x28

# on_tag:

# then:

# - rtttl.play: "success:d=24,o=5,b=100:c,g,b"

# - homeassistant.tag_scanned: !lambda 'return x;'

rtttl:

output: buzzer

sensor:

- platform: rotary_encoder

id: encoder

pin_a: GPIO40

pin_b: GPIO41

on_clockwise:

then:

- if:

condition:

switch.is_on: menu_sounds

then:

- rtttl.play: ${menu_sound}

- if:

condition:

display.is_displaying_page: home

then:

- lambda: |-

if (id(device) == 8) {

id(device) = 1;

}

else {

id(device) += 1;

}

- if:

condition:

display.is_displaying_page: device_control

then:

- if:

condition:

lambda: |-

return id(device) == 1;

then:

- homeassistant.action:

service: light.turn_on

data:

entity_id: ${desk_led}

brightness_step_pct: '10'

- if:

condition:

lambda: |-

return id(device) == 2;

then:

- homeassistant.action:

service: climate.set_temperature

data:

entity_id: ${climate}

data_template:

temperature: '{{ my_variable | float }}'

variables:

my_variable: |-

return id(thermostat_temperature).state + 1.0;

- if:

condition:

lambda: |-

return id(device) == 3;

then:

- homeassistant.action:

service: vacuum.return_to_base

data:

entity_id: ${vacuum}

- if:

condition:

lambda: |-

return id(device) == 6;

then:

- homeassistant.action:

service: climate.set_temperature

data:

entity_id: ${aircon}

data_template:

temperature: '{{ my_variable | float }}'

variables:

my_variable: |-

return id(aircon_temperature).state + 1.0;

- if:

condition:

lambda: |-

return id(device) == 7;

then:

- homeassistant.action:

service: humidifier.set_humidity

data:

entity_id: ${dehumidifier}

data_template:

humidity: '{{ my_variable | float }}'

variables:

my_variable: |-

return id(dehumidifier_humidity).state + 5.0;

- if:

condition:

lambda: |-

return id(device) == 8;

then:

- homeassistant.action:

service: light.turn_on

data:

entity_id: ${lamp}

brightness_step_pct: '10'

- lambda: |-

id(inactivity_time) = 0;

on_anticlockwise:

then:

- if:

condition:

switch.is_on: menu_sounds

then:

- rtttl.play: ${menu_sound}

- if:

condition:

display.is_displaying_page: home

then:

- lambda: |-

if (id(device) == 1) {

id(device) = 8;

}

if (id(device) == 0) {

id(device) = 8;

}

else {

id(device) -= 1;

}

- if:

condition:

display.is_displaying_page: device_control

then:

- if:

condition:

lambda: |-

return id(device) == 1;

then:

- homeassistant.action:

service: light.turn_on

data:

entity_id: ${desk_led}

brightness_step_pct: '-10'

- if:

condition:

lambda: |-

return id(device) == 2;

then:

- homeassistant.action:

service: climate.set_temperature

data:

entity_id: ${climate}

data_template:

temperature: '{{ my_variable | float }}'

variables:

my_variable: |-

return id(thermostat_temperature).state - 1.0;

- if:

condition:

lambda: |-

return id(device) == 3;

then:

- if:

condition:

lambda: 'return id(device_vacuum).state == "cleaning";'

then:

- homeassistant.action:

service: vacuum.pause

data:

entity_id: ${vacuum}

else:

- homeassistant.action:

service: vacuum.start

data:

entity_id: ${vacuum}

- if:

condition:

lambda: |-

return id(device) == 6;

then:

- homeassistant.action:

service: climate.set_temperature

data:

entity_id: ${aircon}

data_template:

temperature: '{{ my_variable | float }}'

variables:

my_variable: |-

return id(aircon_temperature).state - 1.0;

- if:

condition:

lambda: |-

return id(device) == 7;

then:

- homeassistant.action:

service: humidifier.set_humidity

data:

entity_id: ${dehumidifier}

data_template:

humidity: '{{ my_variable | float }}'

variables:

my_variable: |-

return id(dehumidifier_humidity).state - 5.0;

- if:

condition:

lambda: |-

return id(device) == 8;

then:

- homeassistant.action:

service: light.turn_on

data:

entity_id: ${lamp}

brightness_step_pct: '-10'

- lambda: |-

id(inactivity_time) = 0;

- platform: homeassistant

id: desk_led_brightness

entity_id: ${desk_led}

attribute: brightness

internal: true

filters:

- lambda: |-

if (isnan(x)) { return 0; }

else { return x; }

- platform: homeassistant

id: thermostat_temperature

entity_id: ${climate}

attribute: temperature

internal: true

- platform: homeassistant

id: aircon_temperature

entity_id: ${aircon}

attribute: temperature

internal: true

- platform: homeassistant

id: dehumidifier_humidity

entity_id: ${dehumidifier}

attribute: humidity

internal: true

- platform: homeassistant

id: lamp_brightness

entity_id: ${lamp}

attribute: brightness

internal: true

filters:

- lambda: |-

if (isnan(x)) { return 0; }

else { return x; }

spi:

id: spi_bus

mosi_pin: GPIO5

clk_pin: GPIO6

switch:

- platform: template

name: "Auto Lock"

id: auto_lock

icon: "mdi:lock-clock"

optimistic: true

restore_mode: 'restore_default_off'

- platform: template

name: "Display"

id: mravocado_display

icon: "mdi:fit-to-screen"

optimistic: true

restore_mode: 'always_on'

on_turn_on:

- light.turn_on:

id: backlight

brightness: 100%

- lambda: |-

id(inactivity_time) = 0;

on_turn_off:

- light.turn_off: backlight

- display.page.show: home

- lambda: |-

id(device) = 0;

- platform: template

name: "Screen Saver"

id: screen_saver

icon: "mdi:screen-rotation-lock"

optimistic: true

restore_mode: 'always_off'

internal: true

on_turn_on:

- light.turn_on:

id: backlight

brightness: 50%

- display.page.show: locked_screen

- lambda: |-

id(device) = 0;

- platform: template

name: "Menu Sounds"

id: menu_sounds

icon: "mdi:playlist-music"

optimistic: true

restore_mode: 'restore_default_on'

text_sensor:

- platform: homeassistant

id: device_desk_led

entity_id: ${desk_led}

internal: true

- platform: homeassistant

id: device_thermostat

entity_id: ${climate}

internal: true

- platform: homeassistant

id: device_vacuum

entity_id: ${vacuum}

internal: true

- platform: homeassistant

id: device_printer

entity_id: ${printer}

internal: true

- platform: homeassistant

id: device_printer3d

entity_id: ${printer3d}

internal: true

- platform: homeassistant

id: device_dehumidifier

entity_id: ${dehumidifier}

internal: true

- platform: homeassistant

id: device_aircon

entity_id: ${aircon}

internal: true

- platform: homeassistant

id: device_lamp

entity_id: ${lamp}

internal: true

time:

# RTC

- platform: pcf8563

id: rtctime

i2c_id: internal_i2c

address: 0x51

update_interval: never

- platform: homeassistant

id: esptime

on_time_sync:

then:

- pcf8563.write_time:

touchscreen:

- platform: ft5x06

id: touchscreen_mravocado

i2c_id: internal_i2c

address: 0x38

display:

- platform: ili9xxx

id: round_display

model: GC9A01A

cs_pin: GPIO7

reset_pin: GPIO8

update_interval: 0.05s

dc_pin: GPIO4

invert_colors: true

pages:

- id: locked_screen

lambda: |-

it.fill(id(background_color));

it.image(0, 0, id(background_image_saver));

it.strftime(120, 40, id(clock_time), TextAlign::CENTER, "%H:%M", id(esptime).now());

it.strftime(120, 200, id(secondary), TextAlign::CENTER, "%d/%m/%y", id(esptime).now());

- id: home

lambda: |-

it.fill(id(background_color));

it.image(0, 0, id(background_image));

if (id(device) == 1) { it.image(103, 4, id(icon_1), id(icon_on)); }

else { it.image(103, 4, id(icon_1), id(icon_off)); }

if (id(device) == 2) { it.image(175, 35, id(icon_2), id(icon_on)); }

else { it.image(175, 35, id(icon_2), id(icon_off)); }

if (id(device) == 3) { it.image(205, 105, id(icon_3), id(icon_on)); }

else { it.image(205, 105, id(icon_3), id(icon_off)); }

if (id(device) == 4) { it.image(175, 175, id(icon_4), id(icon_on)); }

else { it.image(175, 175, id(icon_4), id(icon_off)); }

if (id(device) == 5) { it.image(103, 205, id(icon_5), id(icon_on)); }

else { it.image(103, 205, id(icon_5), id(icon_off)); }

if (id(device) == 6) { it.image(30, 175, id(icon_6), id(icon_on)); }

else { it.image(30, 175, id(icon_6), id(icon_off)); }

if (id(device) == 7) { it.image(5, 105, id(icon_7), id(icon_on)); }

else { it.image(5, 105, id(icon_7), id(icon_off)); }

if (id(device) == 8) { it.image(30, 35, id(icon_8), id(icon_on)); }

else { it.image(30, 35, id(icon_8), id(icon_off)); }

- id: device_control

lambda: |-

it.fill(id(background_color));

it.image(0, 0, id(background_image_device));

it.image(98, 10, id(icon_home), id(light_orange));

if (id(device) == 1) {

if (id(device_desk_led).state == "on") { it.image(70, 80, id(icon_1_big), id(icon_big_on)); }

else { it.image(70, 80, id(icon_1_big), id(icon_big_off)); }

it.image(25, 115, id(minus), id(light_orange));

it.printf(120, 210, id(secondary), TextAlign::CENTER, "%.0f %%", ((id(desk_led_brightness).state / 255) * 100));

it.image(185, 115, id(plus), id(light_orange));

}

if (id(device) == 2) {

if (id(device_thermostat).state == "heat") { it.image(70, 80, id(icon_2_big), id(icon_big_on)); }

else { it.image(70, 80, id(icon_2_big), id(icon_big_off)); }

it.image(25, 115, id(minus), id(light_orange));

it.printf(120, 210, id(secondary), TextAlign::CENTER, "%.1f°C", id(thermostat_temperature).state);

it.image(185, 115, id(plus), id(light_orange));

}

if (id(device) == 3) {

if (id(device_vacuum).state == "cleaning") { it.image(70, 80, id(icon_3_big), id(icon_big_on)); }

else { it.image(70, 80, id(icon_3_big), id(icon_big_off)); }

if (id(device_vacuum).state == "cleaning") {

it.image(25, 115, id(pause_icon), id(light_orange));

}

else {

it.image(25, 115, id(play_icon), id(light_orange));

}

it.printf(120, 210, id(secondary), TextAlign::CENTER, "%s", id(device_vacuum).state.c_str());

it.image(185, 115, id(vacuum_dock), id(light_orange));

}

if (id(device) == 4) {

if (id(device_printer).state == "on") { it.image(70, 80, id(icon_4_big), id(icon_big_on)); }

else { it.image(70, 80, id(icon_4_big), id(icon_big_off)); }

it.printf(120, 210, id(secondary), TextAlign::CENTER, "%s", id(device_printer).state.c_str());

}

if (id(device) == 5) {

if (id(device_printer3d).state == "on") { it.image(70, 80, id(icon_5_big), id(icon_big_on)); }

else { it.image(70, 80, id(icon_5_big), id(icon_big_off)); }

it.printf(120, 210, id(secondary), TextAlign::CENTER, "%s", id(device_printer3d).state.c_str());

}

if (id(device) == 6) {

if (id(device_aircon).state == "cool") { it.image(70, 80, id(icon_6_big), id(icon_big_on)); }

else { it.image(70, 80, id(icon_6_big), id(icon_big_off)); }

it.image(25, 115, id(minus), id(light_orange));

it.printf(120, 210, id(secondary), TextAlign::CENTER, "%.1f°C", id(aircon_temperature).state);

it.image(185, 115, id(plus), id(light_orange));

}

if (id(device) == 7) {

if (id(device_dehumidifier).state == "on") { it.image(70, 80, id(icon_7_big), id(icon_big_on)); }

else { it.image(70, 80, id(icon_7_big), id(icon_big_off)); }

it.image(25, 115, id(minus), id(light_orange));

it.printf(120, 210, id(secondary), TextAlign::CENTER, "%.1f°C", id(dehumidifier_humidity).state);

it.image(185, 115, id(plus), id(light_orange));

}

if (id(device) == 8) {

if (id(device_lamp).state == "on") { it.image(70, 80, id(icon_8_big), id(icon_big_on)); }

else { it.image(70, 80, id(icon_8_big), id(icon_big_off)); }

it.image(25, 115, id(minus), id(light_orange));

it.printf(120, 210, id(secondary), TextAlign::CENTER, "%.0f %%", ((id(lamp_brightness).state / 255) * 100));

it.image(185, 115, id(plus), id(light_orange));

}

⚠️ While we’ve managed to implement all these features for Mr. Avocado, my recommendation is to comment out (or remove) any parts of the code you’re not planning to use. This will help improve the device’s performance and prevent it from freezing.

6. This code does not include the credentials needed for your device to connect to your Wi-Fi network and your Home Assistant instance. You’ll need to add them manually.

Specifically, I’m referring to the following lines from the code you copied in Step 4.

# Enable Home Assistant API

api:

encryption:

key: "bg6hash6sjdjsdjk02hh0qnQeYVwm123vdfKE8BP5"

ota:

- platform: esphome

password: "asddasda27aab65a48484502b332f"

wifi:

ssid: !secret wifi_ssid

password: !secret wifi_password

# Enable fallback hotspot (captive portal) in case wifi connection fails

ap:

ssid: "Assist Fallback Hotspot"

password: "ZsasdasdHGP2234"

7. What you need to do is to find the corresponding lines in the code (they’re at the top) and add your Wi-Fi and Home Assistant credentials there.

8. Now, click “Save” and then “Install.” Choose “Manual download” and wait for the code to compile.

9. Once the compilation is complete, select the “Modern format” option to download the corresponding .bin file.

10. Connect the M5Stack Dial to your computer using a USB-C data cable via the port on the bottom of the device.

11. Next, go to the ESPHome web page and click “Connect.” In the popup window, select your board and click “Connect.”

12. Then click “Install” again and choose the .bin file you downloaded in step 9. Click “Install” once more to flash the firmware.

13. Return to Home Assistant and go to Settings > Devices & Services.

In most cases, your device should be automatically discovered and appear at the top, waiting for you to click “Configure.”

If not, click “Add Integration,” search for “ESPHome,” and enter your board’s IP address in the Host field. As always, it’s a good idea to assign a static IP to your device in your router settings to avoid connection issues later on.

14. To finish, go to Settings > Devices & Services > ESPHome, click the “Configure” link next to your device, and in the popup window, check the box that says, “Allow this device to make Home Assistant API calls,” then click “Submit.”

This will allow us to control devices directly from the screen.

Alright, you’ve successfully integrated the M5Stack Dial into Home Assistant as Mr. Avocado. Now let’s go over how to take full advantage of its features.

To protect the screen, we’ve added a customizable screensaver function. You can easily tweak it by accessing the entities exposed by the device in Home Assistant. Pay special attention to these three controls.

After a few seconds of inactivity (you can set the duration using the “Screen Saver” slider), the menu automatically hides, showing the clock and date with reduced screen brightness.

Additionally, if you enable “Auto Lock,” the screen will turn off completely a few seconds later (adjustable using the “Auto Lock” slider).

Of course, you can use our default Mr. Avocado background images — or replace them with your own.

Just update the image references in the first few lines of the code to point to your preferred files.

substitutions:

# Device customization

# Personalización del dispositivo

background_image: https://aguacatec.es/wp-content/uploads/2025/02/mravocado_background_white.jpg

background_image_saver: https://aguacatec.es/wp-content/uploads/2025/02/mravocado_bg_off.jpg

background_image_device: https://aguacatec.es/wp-content/uploads/2025/02/mravocado_bg_device.jpeg

You can also customize which devices you want to control and the icons that represent them. Throughout the code, you’ll find examples for controlling different types of entities—lights, climate, vacuum, switches, humidifiers, and more. But if you understand the logic, you can control any Home Assistant device!

The example menu is optimized for 8 devices, but you can add more icons or even paginate the menu. Plus, if you press on any device, you’ll see advanced controls using the rotary encoder.

Since Mr. Avocado has a built-in buzzer, you can use it as an alarm or timer, making it sound whenever you want. Just use the “Alarm” button entity exposed by the device. You can also enable or disable a beep sound when navigating through the menu.

By the way, you can customize the alarm tone, as I explained in this article.

substitutions:

# Sounds

# Sonidos

menu_sound: 'beep:d=64,o=5,b=255:c7'

alarm_sound: 'xmen:d=4,o=6,b=200:16f#5,16g5,16b5,16d,c#,8b5,8f#5,p,16f#5,16g5,16b5,16d,c#,8b5,8g5,p,16f#5,16g5,16b5,16d,c#,8b5,8d,2p,8c#,8b5,2p'

Mr. Avocado also includes an NFC/RFID reader, although it’s not its strongest feature — I find the tag detection to be somewhat imprecise.

Still, if you want to use it, be sure to check out this article where I explain in detail how to create automations for each specific tag.

By the way, if you like it, you can also get our custom Mr. Avocado stand!

Thanks to the threaded mount built into the M5Stack Dial, attaching it is very easy. Just screw the device onto the stand’s base and route the USB-C power cable through the rear opening.

I recommend using a 90º angled USB-C cable to make positioning easier (although you can also rotate the screen to your liking).

Also, keep in mind the case has space at the top and an opening at the bottom—both intentionally designed so you can access the two expansion ports (I2C and GPIO) to add your favorite sensors.

⭐ If you have a 3D printer, you can download this stand I designed from our Patreon profile. If not, you can also purchase it from La R3D and have it shipped to your home!

Source: AguacaTEC

Author: TitoTB

Launched in October 2023 by M5Stack, the StickC Plus2 has quickly become a popular choice among makers, educators, and embedded system developers. It’s widely used in IoT projects, embedded systems, and cybersecurity applications. Many users even compare it with Flipper Zero as affordable alternatives for their similar roles in wireless testing and cybersecurity tools.

In this article, we’ll walk you through the StickC Plus2’s key features, programming options, and practical project ideas.

The M5StickC Plus2 is a compact, all-in-one ESP32-S3 development board designed for rapid prototyping and embedded applications. It integrates a 1.14” TFT display, IMU, microphone, infrared transmitter, and rechargeable battery — all within an ultra-portable form factor.

With support for Arduino, UIFlow2, and MicroPython, the StickC Plus2 is well-suited for a wide range of applications, from IoT devices and wearable interfaces to educational tools and lightweight cybersecurity projects.

M5StickC Plus2 builds on the StickC Plus with a new ESP32-PICO-V3-02 chip, increased battery capacity, improved Wi-Fi and infrared performance, and an upgraded CH9102 UART for more stable USB communication. However, the original StickC Plus has a built-in battery management IC that Plus2 lacks.

Additionally, the two devices differ slightly in their power-on and power-off behavior.

M5StickC Plus2 is a compact ESP32-S3 board ideal for developers looking to build custom IoT or cybersecurity tools. With third-party firmware (Like Bruce), it can emulate some Flipper Zero features like RF, IR, and USB HID.

Flipper Zero, on the other hand, is a ready-made hacking device with built-in wireless protocols, perfect for users who want an all-in-one security testing tool without programming.

Designed for the ESP32 microcontroller platform, Bruce merges Wi-Fi, RF (Radio Frequency), BLE (Bluetooth Low Energy), IR, and USB capabilities into a single, modular offensive toolkit tailored for red team activities and security research.

The easiest way to install Bruce on your M5Stack device is with M5Burner, M5Stack’s official firmware flashing tool.

If you haven’t downloaded it yet, click here to get started.

Open M5Burner > Select STICKC > Scroll down and you’ll see Bruce for StickC plus2 (or simply type “Bruce” into the search bar to locate it quickly.)

Click Download > Connect your device via a USB cable > Click Burn, select the corresponding USB port and default baud rate 1500000 > Hit Start to begin flashing

Note: Bruce is an open-source, community-developed firmware project not officially affiliated with M5Stack. A warning may pop up when you download the firmware.

Once you see the message "Burn successfully, click here to return", click it to finish, and press the reset button on your device once to let it start. Now you can begin exploring its features!

Note: If any issues occur during flashing, you may need to install a USB driver on your computer, or long-press the reset button on the main controller to enter download mode. For details, refer to the documentation page of your specific main controller device.

⚠️ Disclaimer: All use must comply with local laws. Use only for educational or testing purposes on your own devices.

1. Wi-Fi Attacks: Beacon flooding, deauthentication, EvilPortal phishing pages, EAPOL handshake capture, ARP spoofing, and wardriving GPS mapping.

The captive portal is one of Bruce’s most well-known features, commonly used for Wi-Fi phishing attacks. To launch it, go to Wi-Fi > Evil Portal, enter the target Wi-Fi name, and specify an IP address (or use the default). The phishing portal will begin broadcasting immediately.

On the screen, you'll see two URLs, these are used to view captured credentials and spoofed SSIDs. When a user attempts to log in through the fake portal, their credentials are captured by the device.

Public Wi-Fi networks present inherent security risks. It is advisable to avoid using such networks whenever possible. If usage is necessary, refrain from logging into personal accounts or transmitting sensitive information to minimize potential exposure.

2. Infrared & BadUSB: Offers IR transmission and reception, along with USB HID keyboard / mouse simulation on supported boards.

For example, navigate to the main menu, select the BadUSB section, choose a script, then run it to start USB keystroke injection. You can also watch this quick video by Pirata to see it in action: https://www.youtube.com/shorts/F_7QlGVx-XU

3. Sub-GHz & RF Hacking: Integrates modules like CC1101 and NRF24 for jamming, scanning, and replaying RF signals.

4. RFID / NFC Tools: Uses the PN532 chip to support Mifare Ultralight tag emulation, reading, writing, and P2P communication.

5. Bluetooth LE: Scanning, beacon broadcasting, and early BLE payload experiments were implemented as early as version 1.3.

6. Web Interface & Scripting: Features a full web UI for module control, LittleFS/SD card file management, and an integrated JavaScript scripting interface for automation and extension.

Bruce is licensed under the AGPL-3.0 for its firmware, emphasizing true software freedom. It supports a variety of ESP32 and ESP32-S3 development boards, except for the M5StickC Plus2, it's also suitable for: Cardputer, Core1 (Basic), Core2, CoreS3 / SE, StickC-Plus. It lowers the barrier for both beginners and experts looking to dive into embedded offensive tooling.

Meshtastic is an open-source, off-grid communication project that uses LoRa (Long Range) radio technology to enable secure, long-distance messaging without the internet or cellular networks. It leverages point-to-point(P2P) and mesh communication in areas with no internet or cellular access by forming a self-sufficient network of devices. Utilizing ultra-low power hardware and license-free frequency bands, it enables long-range message transmission, making it ideal for outdoor adventures, emergency rescue, rural connectivity, and low-power IoT applications.

In this guide, we'll walk you through building your very own Meshtastic LoRa node using Module LoRa868 and ESP32-based M5Stack Core series controllers.

What You’ll Need

The easiest way to install Meshtastic firmware on your M5Stack device is with M5Burner, a simple and free intuitive firmware flashing tool developed by M5Stack.

1. Locate the Meshtastic Firmware

Open M5Burner > Select ALL from the list in the left column > Input "Meshtastic" into the search bar and choose the firmware that match your device > Click Download.

If you haven’t installed M5Burner, click here and follow the installation steps to download it to your computer.

2. Connect Your Device and Start Flashing

– Connect the main controller to your computer via USB data cable > Click Burn > Select the correct USB port and set baud rate to 1500000 > Click Start to begin flashing.

– Wait for the message "Burn successfully" > Click "Click here to return" > When the Meshtastic logo "//\" appears on the screen, disconnect the device from your computer.

Note: if flashing fails, try installing the USB driver on your computer or long-press the reset button on the main controller to enter download mode. For more information, refer to your device’s documentation page.

After the firmware successfully downloaded on the device:

– Check M5Burner firmware for pin info and set DIP switches by following Module LoRa868 v1.2 DIP Switch Guide (for Core1/Core2: long pins 2,5,7 and short pin 1 ON).

– Remove red dust cap > Install antenna > Connect the module to the device.

– Power on the device, then the Meshtastic logo "//\" will appear.

Safety Warning

Do NOT connect or power on the device without installing the antenna, as this may cause permanent hardware damage!

1. Install the Meshtastic app on Your Phone

Download the Meshtastic app from the Google Play or Download APK from GitHub(for Android) or App Store(for IOS).

2. Pair the Device

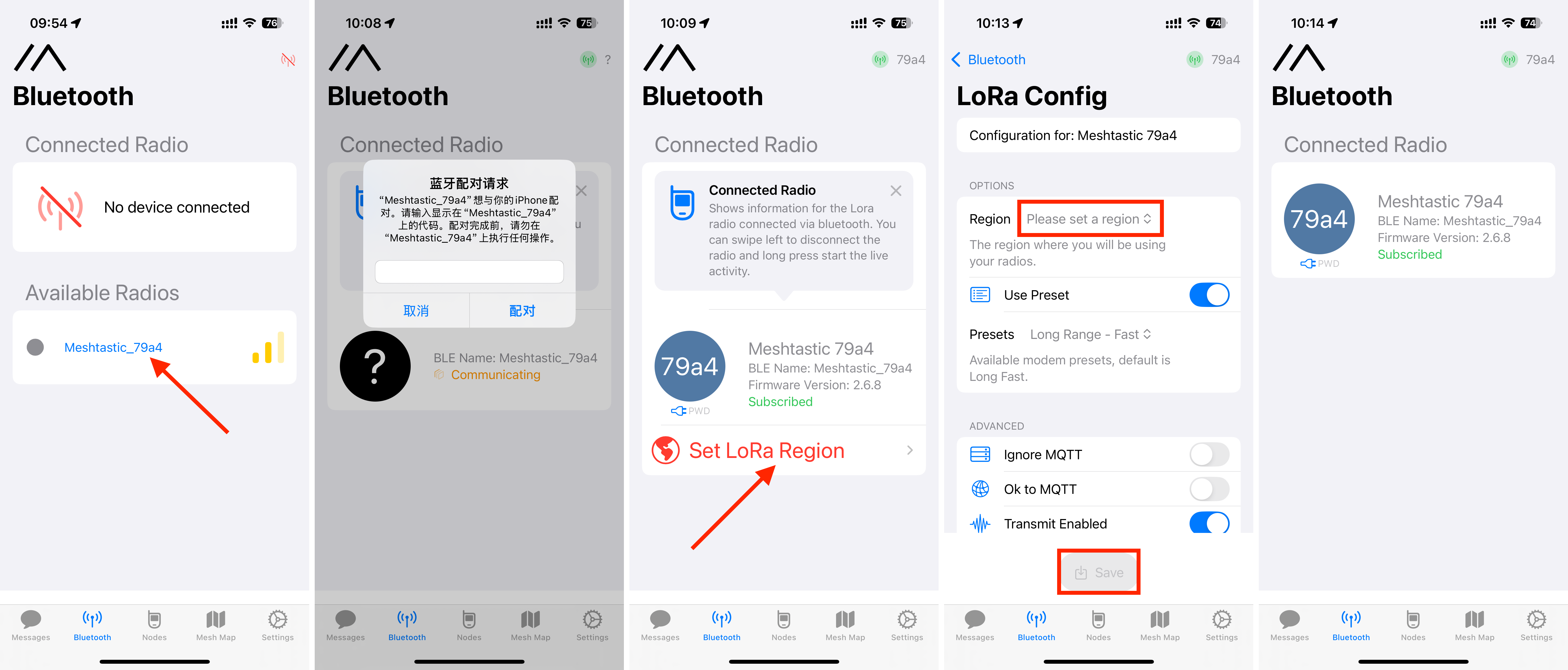

Open the Meshtastic app and follow the on-screen instructions to pair your device via Bluetooth—nearby devices will be detected automatically. The iOS and Android Meshtastic apps offer similar features but have different interfaces, so setup steps and screenshots are shown separately for each platform.

3. Configure Device Settings

After pairing, you could set the Lora region, select the appropriate region (e.g., EU 868MHz), username in the app.

When running Meshtastic, the ESP32 can't use Wi-Fi and Bluetooth simultaneously. Bluetooth is enabled by default. If you turn on Wi-Fi, Bluetooth will be disabled. To re-enable it, connect the device to your computer via USB and use the Meshtastic Web Client in Chrome to disable Wi-Fi.

Step 4: Add GPS To Your Meshtastic Node

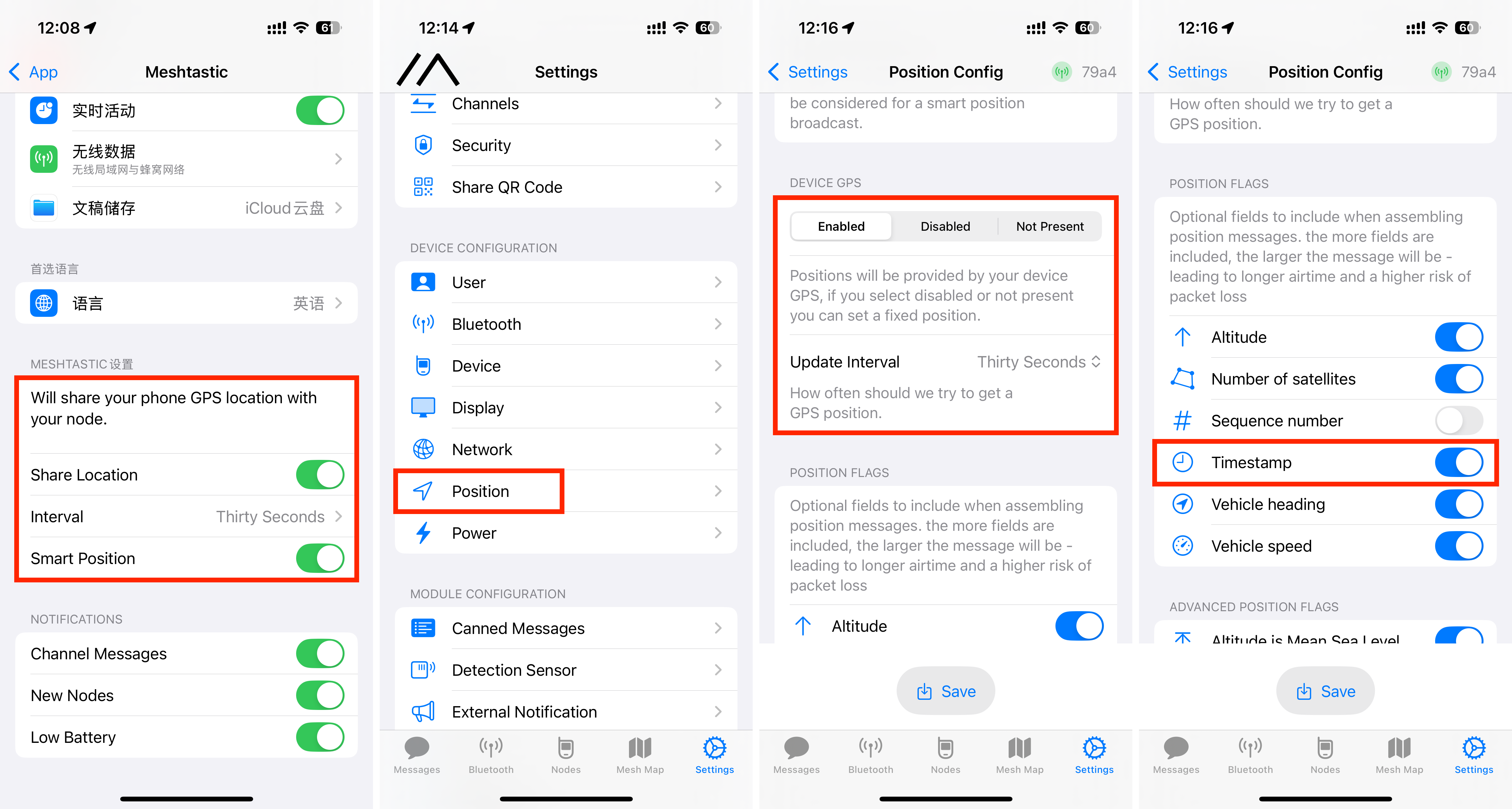

Core1/Core2 with LoRa868 v1.2 doesn’t have built-in GPS, but you can share your smartphone’s GPS location with the device. It's useful for team members to track each other during outdoor activities.

Step 5: Send and Receive Message

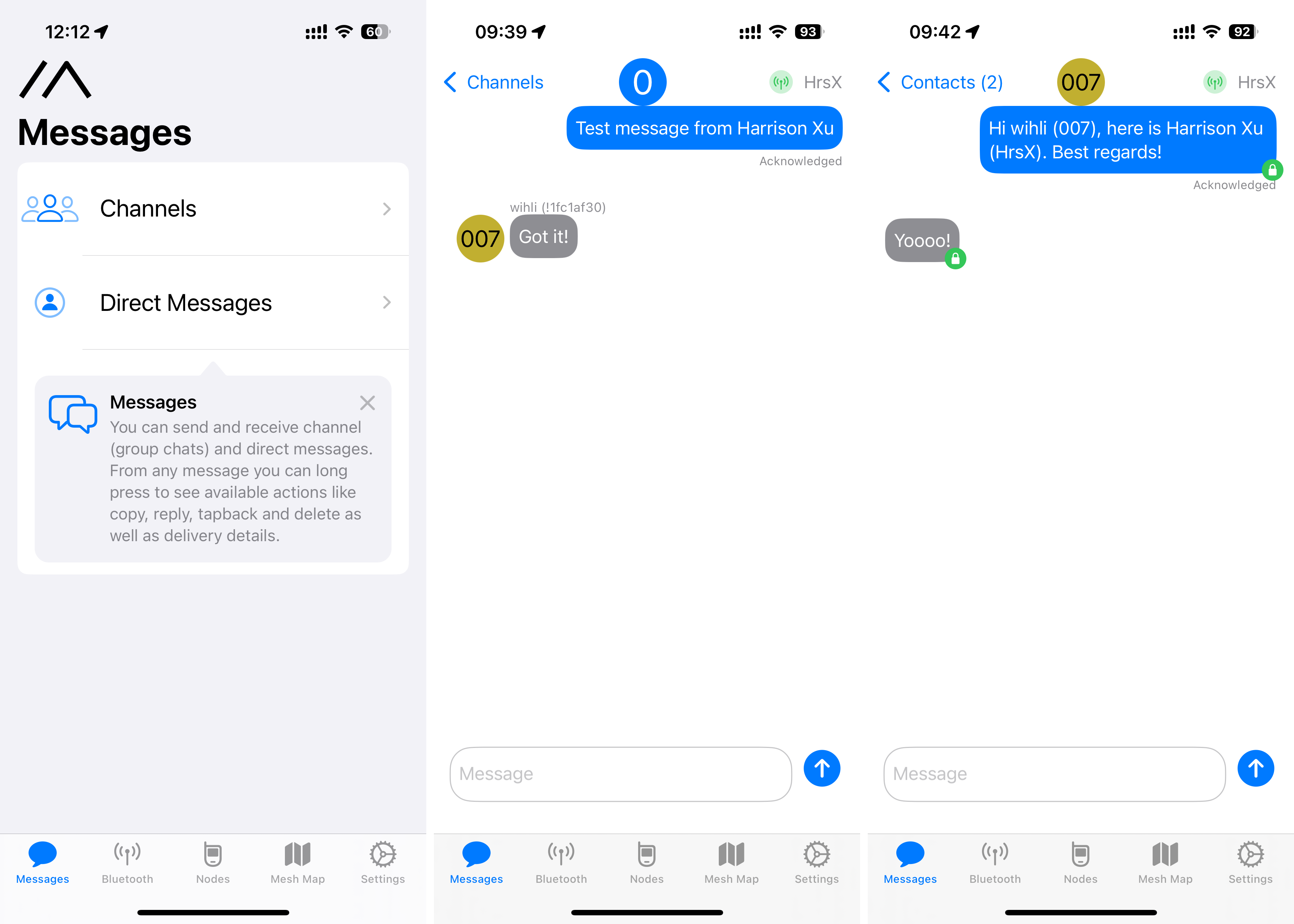

With other nodes show up in the list, you're connected to the mesh and can start messaging via the Meshtastic app.

Is Meshtastic Legal?

Yes, it’s legal. Meshtastic operates on license-free frequency bands such as 433 / 470 / 868 / 915 MHz which is in full compliance with FCC regulations.

How far does Meshtastic work?

The estimated range of this Meshtastic setup is around 4 km (2.49 miles). But the range between two Meshtastic nodes varies based on antenna setup, and environmental conditions. You may try moving the device around to test the range, check the signal to ensure stable connectivity.